Choosing the Right Hoses for Oxygen and Acetylene Welding Applications

The Importance of Oxygen and Acetylene Hoses in Welding

Oxygen and acetylene hoses play a crucial role in the field of welding, especially when it comes to the oxy-acetylene welding process. This method, known for its versatility and effectiveness, relies heavily on the proper use of these hoses to deliver gases safely and efficiently, making them an integral part of any welder's equipment.

Understanding the Basics

Oxy-acetylene welding utilizes a flame produced by burning acetylene gas in the presence of oxygen. This type of welding is characterized by its ability to reach high temperatures, making it suitable for welding a wide variety of metals, including steel and aluminum. The two primary gases—oxygen and acetylene—are stored in separate cylinders and connected to a welding torch via specialized hoses. The hoses are typically color-coded for safety the oxygen hose is green, while the acetylene hose is red.

Construction and Safety Features

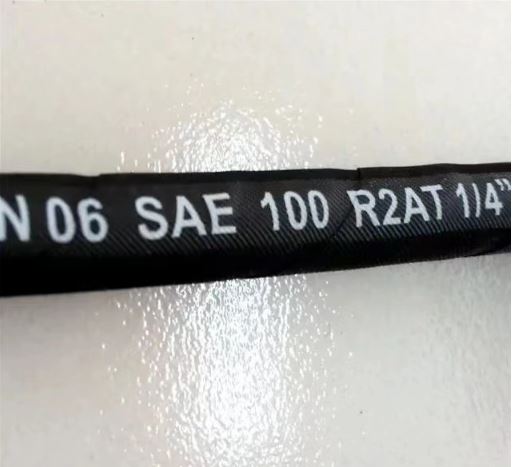

The construction of oxygen and acetylene hoses is designed to withstand the high pressures and temperatures involved in the welding process. These hoses are commonly made from durable rubber or thermoplastic materials, which are reinforced with multiple layers to prevent bursting and leaks. One of the critical features of these hoses is that they are designed to be non-permeable, ensuring that the gases do not escape and that the working environment remains safe.

Safety is paramount in welding operations. Manufacturers equip hoses with features such as flame-resistant materials and external markers to indicate pressure limits. It’s also essential for users to regularly inspect hoses for signs of wear or damage, such as cracks or abrasions, as compromised hoses can lead to dangerous situations, including gas leaks or explosions.

Proper Handling and Maintenance

oxygen and acetylene hoses

To ensure the longevity and safety of oxygen and acetylene hoses, proper handling and maintenance are essential. Hoses should be stored in a clean, dry place away from direct sunlight and extreme temperatures to prevent deterioration. When connecting or disconnecting hoses from the welding torch or gas cylinders, users should always shut off the gas supply first and release any remaining pressure within the hoses.

Regular inspection is vital. Welders should look for frays, kinks, or any other signs of damage before each use. It’s also essential to ensure that the fittings are secure and that there are no leaks. A simple leak test can be performed by applying a soap solution to the connections—bubbles will form if there is a leak.

Understanding Safe Operating Procedures

When working with oxygen and acetylene hoses, adhering to safe operating procedures is crucial. Users should always wear appropriate personal protective equipment (PPE), including safety glasses, gloves, and flame-resistant clothing. It is also important to ensure that the work area is well-ventilated to avoid the buildup of hazardous gases.

Welders should also be trained in the correct use of their equipment, including how to adjust the flame produced by the oxy-acetylene torch. Understanding the characteristics of the flame—neutral, oxidizing, or carburizing—allows welders to achieve the best results based on the specific materials they are working with.

Conclusion

In summary, oxygen and acetylene hoses are not just simple accessories in the welding process; they are vital components that ensure the efficiency and safety of welding operations. With the proper care, maintenance, and understanding of best practices, welders can minimize risks and maximize the effectiveness of their work. Whether you are a seasoned professional or a budding hobbyist, prioritizing the cleanliness, integrity, and proper usage of these hoses will enhance your welding experience and outcomes. The art of welding is only as strong as its weakest link, and that link often begins with the hoses that deliver life-sustaining gases.

-

The Essential Role of LPG Hoses in Safe and Efficient Gas DistributionNewsJul.16,2025

-

The Crucial Role and Varieties of LPG Gas HosesNewsJul.16,2025

-

PVC Flexible Hoses in Industrial Applications: A Comprehensive OverviewNewsJul.16,2025

-

High - Pressure LPG Hoses - Ensuring Safety and Efficiency in Fuel TransferNewsJul.16,2025

-

Essential Tools for Welding Operations: Oxy - Acetylene HosesNewsJul.16,2025

-

Essential Connections - LP Gas Hoses and Their VariantsNewsJul.16,2025