discharge hoses

Understanding Discharge Hoses Key Features and Applications

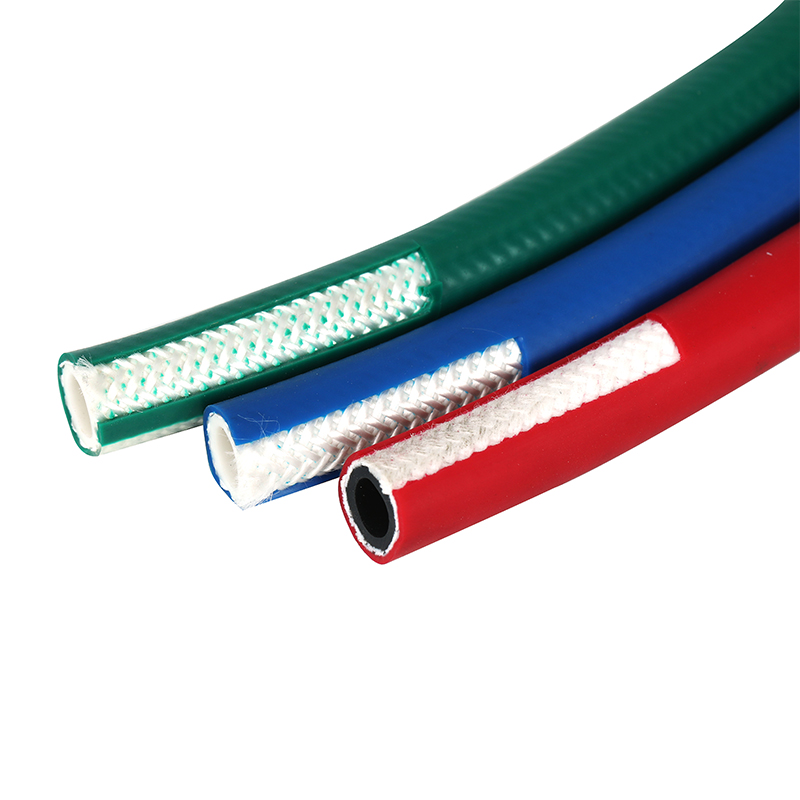

Discharge hoses are critical components in a wide range of industries, serving essential functions in fluid transfer and management. These hoses are specifically designed to transport fluids away from a source, typically from storage tanks, pumps, or other containers. Their robust design and adaptability make them suitable for various applications, from agriculture to construction to industrial processes.

Key Features of Discharge Hoses

1. Material Composition Discharge hoses can be constructed from a variety of materials, including rubber, PVC, and thermoplastic polyurethane. The choice of material often depends on the type of fluid being transferred. For instance, rubber hoses are favored for their durability and flexibility, making them ideal for heavy-duty applications. In contrast, PVC hoses tend to be lighter and more affordable, suitable for less demanding tasks.

2. Pressure Rating Discharge hoses are rated for specific pressure levels, and selecting the appropriate hose is crucial to ensure safety and performance. Low-pressure hoses are used for gravity-fed systems, while high-pressure variants are necessary for applications involving pumps. It's important to match the hose’s pressure rating to the equipment and fluids involved to avoid leaks or ruptures.

3. Diameter The diameter of the discharge hose significantly influences flow rate and pressure loss. Larger diameters can transport more fluid faster, which is beneficial for high-volume applications. Conversely, smaller diameters may be adequate for low-flow situations, such as in irrigation systems. It is vital to choose the correct diameter to optimize efficiency and ensure effective fluid management.

4. Temperature Resistance Depending on the application, discharge hoses must often withstand varying temperatures. Some hoses can handle extreme heat or cold, making them suitable for transporting fluids like hot water, chemicals, or petroleum products. Always check the temperature ratings provided by manufacturers to ensure that the chosen hose will perform under expected conditions.

5. Chemical Compatibility For industries handling hazardous materials or corrosive substances, ensuring chemical compatibility is essential. Discharge hoses should be selected based on the specific chemicals being transported to prevent degradation and ensure safety. Many suppliers provide compatibility charts to assist in the selection process.

discharge hoses

Applications of Discharge Hoses

Discharge hoses find applications across multiple industries, each with unique requirements

- Agriculture In the agricultural sector, discharge hoses are used to transfer water for irrigation or to pump liquid fertilizers and pesticides from tanks to fields. Flexibility and resilience in harsh environments make them invaluable in farming practices.

- Construction During construction projects, discharge hoses facilitate the transfer of water for various purposes, including dust suppression and site dewatering. Their ability to withstand tough conditions—such as abrasiveness and exposure to chemicals—ensures reliability on the job site.

- Industrial In manufacturing and processing plants, discharge hoses are utilized for chemical transfer, wastewater management, and even fire prevention systems. Their durability and chemical resistance are crucial for maintaining safety and operational efficiency.

- Marine In the maritime industry, discharge hoses are vital for transferring fuel and bilge water on ships and boats. They must be specifically designed to resist saltwater corrosion and withstand the rigors of marine environments.

Conclusion

Understanding the properties and applications of discharge hoses is crucial for anyone involved in industries that require fluid management. By selecting the right hose based on material, pressure rating, diameter, temperature resistance, and chemical compatibility, businesses can enhance operational efficiency and safety. As technology continues to evolve, advancements in hose design and materials will further improve the capabilities and applications of discharge hoses, ensuring they remain integral to modern industrial operations. Investing time in choosing the correct discharge hose can lead to significant long-term benefits in terms of productivity, safety, and cost-effectiveness.

-

Unrivaled Performance and Applications of PU Pneumatic Hoses and TubesNewsJun.11,2025

-

The Transparent World of Industrial Tubing and Hosing SolutionsNewsJun.11,2025

-

The Intricate World of Pneumatic Conduits: Tubes and HosesNewsJun.11,2025

-

The Dynamic Landscape of Pneumatic Conduits: Unraveling Key ComponentsNewsJun.11,2025

-

The Diverse Applications and Significance of Transparent PVC TubingNewsJun.11,2025

-

High - Pressure Pneumatic Tubing and Systems: An In - Depth LookNewsJun.11,2025