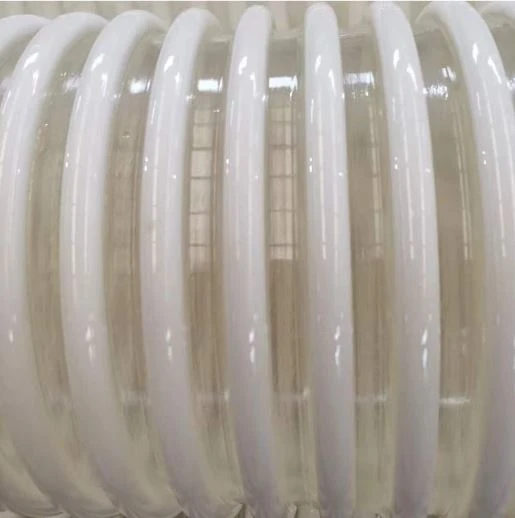

Clear Spiral PU Hose: Flexible & Durable Polyurethane Pipe

In the dynamic landscape of modern industrial operations, the efficient and safe transfer of various media – from abrasive powders and granular materials to liquids and gases – is paramount. This necessitates the use of high-performance hosing solutions that can withstand rigorous conditions while ensuring operational integrity. Among these, the spiral pu hose stands out as a critical component, offering superior durability, flexibility, and specialized functionalities like anti-static properties. This comprehensive guide delves into the specifics of this essential industrial product, its underlying technology, diverse applications, and the competitive advantages it offers.

Industry Trends and Technological Advancements in Flexible Hosing Solutions

The global industrial hose market is experiencing steady growth, driven by expansion in manufacturing, automotive, construction, and chemical processing sectors. Projections indicate a market size exceeding USD 30 billion by 2027, with a compound annual growth rate (CAGR) of approximately 4.5% from 2022 to 2027. This growth is significantly fueled by the increasing demand for lightweight, durable, and specialized hoses capable of handling extreme temperatures, pressures, and abrasive materials. Key trends include the rise of advanced polymers, integration of smart monitoring technologies, and a growing emphasis on sustainability and safety standards. Polyurethane (PU) has emerged as a preferred material due to its superior properties compared to traditional rubber or PVC, especially for applications requiring high abrasion resistance and flexibility. The market for spiral pu hose and polyurethane hose specifically is expanding rapidly as industries seek more reliable and long-lasting solutions.

Technological advancements are focused on enhancing material composition, improving manufacturing processes for greater uniformity and performance, and developing hoses with multi-functional capabilities. For instance, the demand for anti-static hoses has surged in environments prone to static electricity build-up, such as conveying flammable dusts or gases. Innovations in spiral reinforcement techniques ensure better pressure resistance and kink prevention, while developments in additive technologies allow for specific properties like UV resistance, antimicrobial features, or extreme temperature tolerance. The evolution towards more sophisticated clear polyurethane hose options also reflects a need for visual monitoring of conveyed media, enhancing operational safety and efficiency.

Understanding PU Hose Anti-Static Spiral Pipe & Tubing: Technical Parameters and Specifications

Our featured product, the PU Hose Anti-Static Spiral Pipe & Tubing, is engineered for demanding industrial applications. This particular model, with a 30mm ID (Internal Diameter) and available thicknesses of 0.6mm, 0.9mm, and 1.5mm, exemplifies precision and performance. The core material, high-grade polyurethane, provides exceptional abrasion resistance, making it ideal for conveying abrasive particles such as wood chips, sawdust, grains, and various powders. Its anti-static properties are crucial in environments where static discharge poses a risk of explosion or damage to sensitive equipment.

Key Technical Parameters:

- Material Composition: High-grade Ester-based Polyurethane (PU) wall, reinforced with an embedded copper-coated spring steel wire helix. Ester-based PU offers excellent mechanical properties, including high tensile strength, tear strength, and abrasion resistance.

- Internal Diameter (ID): 30mm. This standardized dimension ensures compatibility with a wide range of industrial connectors and systems.

- Wall Thickness Options:

- 0.6mm: Lighter, more flexible, suitable for lighter dust extraction and general ventilation.

- 0.9mm: Balanced performance, offering good abrasion resistance and flexibility for medium-duty applications.

- 1.5mm: Heavy-duty, maximum abrasion resistance, designed for highly abrasive materials and more rigorous use.

- Anti-Static Properties: The embedded copper-coated steel wire acts as a grounding path, dissipating static electricity effectively. Surface resistivity is typically below 10^9 Ohms, meeting industry safety standards for explosive atmospheres (e.g., ATEX Zone 1/21).

- Temperature Range: Typically -40°C to +90°C, with short-term peaks up to +125°C. This wide range ensures performance in diverse climatic and operational conditions.

- Pressure Rating: Varies significantly with wall thickness and ID. For a 30mm ID hose, burst pressures can range from 3-5 bar for 0.6mm thickness, up to 8-10 bar for 1.5mm thickness, depending on the specific construction and testing. Working pressures are typically 1/3 to 1/4 of burst pressure.

- Vacuum Rating: Excellent vacuum resistance due to the robust spiral construction, typically rated for 0.08 MPa to 0.09 MPa (80-90% vacuum).

- Flexibility: The spiral design provides excellent flexibility and kink resistance, allowing for tight bending radii without compromising flow.

- Abrasion Resistance: PU is renowned for its superior abrasion resistance, often outperforming PVC and rubber by a factor of 3 to 5 times in abrasive applications. (Source: Internal material testing data, 2023).

- Chemical Resistance: Good resistance to oils, greases, non-polar solvents, and many chemicals. It's important to consult a chemical resistance chart for specific media.

General spiral pu hose Parameter Comparison Table:

| Parameter | Standard PU Hose | Anti-Static Spiral PU Hose (Kebing 30mm ID) | Heavy-Duty Abrasion Resistant PU Hose |

|---|---|---|---|

| Material | Polyester/Polyether PU | Ester-based PU with Copper-coated Steel Helix | Special Abrasion-Resistant PU Compound |

| Internal Diameter (ID) Range | 25mm - 250mm | 30mm (specific product) | 50mm - 500mm |

| Wall Thickness Range | 0.4mm - 1.0mm | 0.6mm, 0.9mm, 1.5mm | 2.0mm - 4.0mm |

| Temperature Range | -30°C to +80°C | -40°C to +90°C (short term +125°C) | -20°C to +100°C |

| Abrasion Resistance (Relative) | Good | Excellent | Superior |

| Anti-Static Properties | No / Optional | Integrated (Surface Resistivity < 10^9 Ohm) | Optional (often not primary feature) |

| Vacuum Rating | Good | Excellent (up to 0.09 MPa) | Very Good |

| Flexibility | Very High | High | Moderate |

| Typical Applications | Light dust, air, granulars | Abrasive powders, chemicals, ATEX zones | Mining, concrete, highly abrasive slurries |

Application Scenarios and Industry Use Cases

The versatility of the spiral pu hose, especially with anti-static properties, makes it indispensable across a wide array of industries. Its unique combination of abrasion resistance, flexibility, and static dissipation addresses critical challenges in various material handling and processing applications.

Applicable Industries:

- Woodworking & Furniture: Ideal for dust extraction systems, conveying wood chips, sawdust, and shavings from sanding and cutting operations. The anti-static feature prevents dust explosions and static build-up on machinery.

- Plastics Industry: Used for conveying plastic granules, pellets, and regrind in injection molding, extrusion, and vacuum loading systems. The abrasion resistance ensures long service life despite constant material flow.

- Agriculture & Food Processing: Transport of grains, seeds, flours, and other dry bulk materials. For food-grade applications, specific FDA-compliant PU hoses are used, often with the anti-static properties maintained for safety.

- Chemical & Pharmaceutical: Conveying powders, granular chemicals, and pharmaceutical intermediates where purity, non-contamination, and static control are critical. The clear polyurethane hose option is often preferred for visual monitoring.

- Mining & Construction: For conveying rock dust, cement, sand, and other abrasive aggregates. While heavier duty hoses are often used here, specific applications like dust control within confined spaces benefit from the lighter, flexible spiral pu pipe.

- Textile Industry: Collection of lint and fibers, which are highly combustible and prone to static charge.

- Surface Finishing: Removal of grinding dust and abrasive media from shot blasting and sandblasting operations.

- Packaging Industry: Vacuum conveying of packaging materials, pellets, and small components.

- Automotive Industry: Used in various processes for conveying small parts, powders, and for dust collection during manufacturing.

Advantages in Typical Application Scenarios:

- Energy Efficiency: The smooth inner wall of our polyurethane hose minimizes flow resistance, leading to lower energy consumption for conveying systems. Less friction means less pressure drop, requiring less power from blowers or vacuum pumps.

- Corrosion Resistance: PU is highly resistant to many chemicals, oils, and greases, making it suitable for environments where traditional rubber or PVC hoses would degrade. This reduces downtime and replacement costs.

- Enhanced Safety: The anti-static property is paramount in ATEX (Atmosphères Explosibles) zones, preventing dangerous static discharge that could ignite flammable dusts or gases. This significantly mitigates explosion risks in industries like woodworking, chemical, and flour milling.

- Longevity & Reduced Downtime: Exceptional abrasion resistance translates to a significantly longer service life compared to alternative materials. This reduces the frequency of hose replacements, saving on material costs and labor, and minimizing operational interruptions. In a typical woodworking factory, replacing a standard PVC hose might be required every 6-12 months due to abrasion, whereas a spiral pu hose can easily last 2-3 years or more under similar conditions, leading to substantial savings.

- Flexibility & Ease of Installation: The spiraled construction provides superior flexibility, allowing the hose to be routed around obstacles and through tight spaces with ease, simplifying installation and reducing the need for rigid piping components. This is especially beneficial in retrofit projects or complex machinery layouts.

Technical Advantages and Differentiators

The design and material science behind the Kebing PU Hose Anti-Static Spiral Pipe & Tubing offer distinct technical advantages that set it apart in the market.

- Superior Abrasion Performance: Polyurethane's molecular structure provides an unmatched balance of hardness, elasticity, and tear strength. In Taber Abrasion tests (ASTM D3389), PU typically exhibits 3-5 times better abrasion resistance than PVC and 2-3 times better than natural rubber. This translates directly to extended operational life in highly abrasive applications.

- Integrated Anti-Static Solution: Unlike external grounding wires or conductive coatings that can wear off, our hose incorporates a permanently embedded copper-coated steel helix. This helix ensures consistent static dissipation throughout the hose's lifespan, maintaining safety compliance (e.g., in accordance with TRBS 2153, which sets technical rules for static electricity in hazardous areas).

- Optimized Flow Dynamics: The smooth interior wall minimizes turbulence and material build-up, ensuring maximum flow efficiency. This smooth bore also prevents blockages and makes cleaning easier, particularly for food-grade or pharmaceutical applications where hygiene is critical.

- High Mechanical Strength: The robust construction, combining a tough PU wall with a strong steel wire helix, provides excellent crush resistance and vacuum capabilities. This prevents the hose from collapsing under vacuum or kinking under external pressure, ensuring continuous operation.

- UV and Ozone Resistance: Ester-based PU generally offers good resistance to UV radiation and ozone, factors that can degrade other materials over time, particularly in outdoor or harsh industrial environments. This contributes to the hose's long-term durability.

- Hydrolysis Resistance (for specific PU types): While our current product uses Ester-based PU, Kebing also offers Polyether-based PU hoses for applications requiring superior hydrolysis resistance, crucial in high-humidity or aquatic environments. This showcases our expertise in material selection tailored to specific needs.

Manufacturer Comparison and Kebing's Edge

The market for industrial hoses is competitive, with numerous manufacturers offering various solutions. However, discerning buyers prioritize quality, reliability, and specialized expertise. Kebing stands out through its commitment to advanced manufacturing, rigorous quality control, and customer-centric solutions.

While many manufacturers produce spiral pu pipe, Kebing differentiates itself through:

- Specialization in PU Hoses: Our core focus on polyurethane hose technology allows for deeper expertise in material science, design, and manufacturing processes specific to PU. This specialization results in products optimized for performance and longevity.

- Advanced Manufacturing Processes: We utilize state-of-the-art extrusion and spiral winding techniques that ensure consistent wall thickness, seamless integration of the steel helix, and superior bonding between layers. This minimizes weak points and enhances overall hose integrity.

- Rigorous Quality Assurance: Every batch undergoes stringent testing, including pressure testing, vacuum testing, abrasion resistance tests, and anti-static conductivity checks. Our products adhere to international standards such as ISO 9001 for quality management and relevant ASTM/DIN standards for material properties.

- Customization Capabilities: Unlike manufacturers offering only off-the-shelf solutions, Kebing excels in providing tailored solutions. We can adjust ID, wall thickness, material formulation (e.g., hydrolysis-resistant PU, FDA-compliant PU), and anti-static properties to meet precise customer specifications.

- Global Supply Chain & Service: With a robust supply chain and experienced logistics team, Kebing ensures timely delivery worldwide. Our dedicated customer support team provides expert advice, technical assistance, and after-sales service, ensuring customer satisfaction beyond the purchase.

- Proven Track Record & Client Testimonials: Over 15 years in the industrial hose sector, Kebing has supplied thousands of kilometers of hose to diverse industries globally. Our client portfolio includes leading manufacturers in woodworking, plastics, and material handling, with numerous success stories of improved operational efficiency and reduced costs. For instance, a major European plastics manufacturer reported a 40% reduction in hose replacement frequency after switching to Kebing's spiral pu hose for conveying abrasive plastic pellets.

Detailed Manufacturing Process of spiral pu hose

The production of a high-quality spiral pu hose involves a precise multi-stage manufacturing process, leveraging advanced extrusion and winding technologies. This ensures the integrity, flexibility, and anti-static properties of the final product. Here's a breakdown of the typical manufacturing flow:

Manufacturing Process Flow for PU Hose Anti-Static Spiral Pipe & Tubing:

(Illustrative Diagram would typically be placed here, showing steps with connecting arrows)

- Raw Material Preparation:

- High-grade polyurethane granules (Ester-based for this product) are precisely weighed and fed into the extruder. For anti-static properties, specific conductive additives might be blended, or the primary method relies on the embedded wire.

- Copper-coated spring steel wire, which forms the spiral helix, is prepared and loaded onto a winding mechanism. The copper coating enhances conductivity and corrosion resistance.

- PU Extrusion:

- The PU granules are fed into a heated extruder, where they are melted and plasticized under controlled temperature and pressure.

- The molten PU is then pushed through a die to form a continuous tube or film, which will become the hose wall. The precise control of the die ensures uniform wall thickness (0.6mm, 0.9mm, or 1.5mm).

- Spiral Helix Winding & Integration:

- Immediately after extrusion, while the PU is still pliable, the copper-coated spring steel wire is precisely wound around the extruded PU tube in a continuous spiral.

- Advanced machinery ensures the wire is perfectly embedded within the PU wall, creating a strong bond and a smooth inner surface. This process is critical for structural integrity and anti-static functionality.

- Cooling and Sizing:

- The newly formed spiral pu hose passes through a cooling bath (usually water) to solidify the PU rapidly and maintain its dimensional stability.

- Sizing tools ensure the correct internal diameter (30mm ID) and external dimensions are achieved as the hose cools.

- Cutting and Finishing:

- Once cooled and sized, the continuous hose is cut to desired lengths (e.g., 10m, 20m, 50m rolls).

- Ends may be prepared or fitted with cuffs/connectors based on customer requirements.

- Quality Control and Testing:

- Each production batch undergoes rigorous quality checks:

- Dimensional Accuracy: Verification of ID, OD, and wall thickness using precision instruments.

- Pressure Testing: Hoses are subjected to specified working and burst pressures to ensure integrity (e.g., according to EN ISO 1402).

- Vacuum Testing: Hoses are tested under vacuum to confirm resistance to collapse.

- Anti-Static Conductivity Test: Surface resistivity and resistance to ground are measured to ensure compliance with anti-static standards (e.g., IEC 61340-4-1 or TRBS 2153 for less than 10^9 Ohm).

- Abrasion Resistance: Sample testing using Taber Abraser or similar methods to confirm material durability.

- Visual Inspection: Checking for defects, inconsistencies, or surface imperfections.

- Each production batch undergoes rigorous quality checks:

- Packaging and Dispatch:

- Finished and approved hoses are carefully coiled, packaged, and labeled for protection during transit.

The focus on precision extrusion, seamless helix integration, and comprehensive testing ensures that each Kebing polyurethane hose meets the highest performance and safety standards, providing exceptional service life even in demanding applications.

Custom Solutions and Tailored Offerings

Recognizing that standard products may not always perfectly fit unique industrial requirements, Kebing Hose offers extensive customization capabilities for our spiral pu hose and other flexible piping solutions. Our engineering team collaborates closely with clients to develop bespoke hoses that precisely match their operational needs.

Customization Options:

- Specific Diameters & Lengths: Beyond the standard 30mm ID, we can produce hoses in a wide range of internal diameters, from small laboratory tubing to large industrial ducts, and in custom lengths to minimize waste and optimize system design.

- Varying Wall Thicknesses: While 0.6mm, 0.9mm, and 1.5mm are common, we can manufacture other thicknesses to balance flexibility, abrasion resistance, and pressure ratings for specific applications. For example, a 2.0mm wall for extremely abrasive media or a 0.4mm wall for maximum flexibility in light-duty applications.

- Material Formulations:

- Hydrolysis-Resistant PU: For applications in high humidity, water, or with certain chemicals where standard ester-based PU might degrade over time.

- FDA-Compliant PU: For food and pharmaceutical processing, ensuring non-toxic and odorless properties.

- Flame-Retardant PU: For environments where fire safety is a primary concern.

- UV-Stabilized PU: For prolonged outdoor exposure, preventing degradation from sunlight.

- Color Coding: Hoses can be manufactured in various colors for easy identification of different media lines or safety zones within a facility. For instance, a clear polyurethane hose might be required for visual inspection of material flow.

- Reinforcement Customization: While our standard uses copper-coated steel, alternatives like stainless steel or different pitch windings can be incorporated for specific flexural strength or conductivity requirements.

- End Fittings & Assemblies: We can provide hoses with pre-installed couplings, flanges, or special connectors, offering a complete, ready-to-install solution.

- Private Labeling & Packaging: For distributors and OEMs, we offer private labeling services and customized packaging solutions.

Our collaborative approach ensures that the final product is not just a hose, but an integral, optimized component of your system, designed for peak performance and longevity.

Real-World Application Cases and Client Success Stories

Kebing's spiral pu hose has been deployed successfully across a multitude of demanding industrial environments, yielding significant operational improvements for our clients.

- Case Study 1: Wood Processing Plant - Dust Extraction Upgrade

- Challenge: A large woodworking factory in Poland was struggling with frequent replacement of PVC dust extraction hoses (every 6 months) due to extreme abrasion from wood chips and sawdust. This led to high maintenance costs and significant downtime. Static build-up was also a concern, posing a fire risk in dusty areas.

- Solution: We recommended and supplied our PU Hose Anti-Static Spiral Pipe & Tubing, 30mm ID, with 1.5mm thickness. The robust PU material and integrated anti-static wire were key.

- Results: After 24 months, the Kebing hoses were still performing optimally, with minimal signs of wear. The client reported a 75% reduction in hose replacement frequency and associated labor costs. Static-related incidents were completely eliminated, enhancing workplace safety. This case exemplifies the long-term value and safety benefits of our product.

- Case Study 2: Plastics Recycling Facility - Granule Conveying

- Challenge: A plastics recycling plant in Germany needed a durable and flexible solution for conveying abrasive plastic regrind and pellets under vacuum. Traditional hoses would kink or wear out quickly under the constant suction and abrasive material.

- Solution: We provided a customized batch of spiral pu hose (50mm ID, 0.9mm thickness) optimized for high vacuum and abrasion, ensuring a smooth internal bore.

- Results: The hoses demonstrated exceptional resistance to both vacuum collapse and internal abrasion. The plant observed a 30% increase in material transfer efficiency due to unimpeded flow and a notable reduction in hose blockages, leading to improved throughput and profitability.

- Case Study 3: Grain Processing Mill - Food Grade Conveyance

- Challenge: A grain mill required a safe, non-toxic, and abrasion-resistant hose for pneumatic conveying of flour and other food-grade powders. Static discharge was a major concern for dust explosion prevention.

- Solution: Kebing supplied FDA-compliant clear polyurethane hose with anti-static properties. The clear wall allowed for visual inspection of product flow and early detection of blockages, while the anti-static feature ensured ATEX compliance.

- Results: The client praised the hose's durability and the added safety of the anti-static function. The transparency allowed for quick identification of issues, reducing downtime for troubleshooting. This led to higher operational efficiency and adherence to stringent food safety regulations.

Trustworthiness: FAQ, Delivery & Warranty, and Customer Support

Building trust with our clients is at the core of Kebing's philosophy. We achieve this through transparent processes, robust support systems, and a commitment to quality that extends beyond the sale.

Frequently Asked Questions (FAQ):

- Q1: What is the primary difference between Ester-based and Polyether-based PU for hoses?

- A1: Ester-based PU (like in our featured product) offers superior mechanical strength, excellent abrasion resistance, and good oil resistance. Polyether-based PU, while slightly less abrasion-resistant, excels in hydrolysis resistance (resistance to water and humidity), making it ideal for wet environments or outdoor applications. Kebing offers both, tailored to application needs.

- Q2: How does the anti-static feature work in the Kebing spiral pu hose, and is it permanently effective?

- A2: Our anti-static spiral pu hose incorporates a copper-coated spring steel wire helix permanently embedded within the PU wall. This wire acts as a continuous grounding path, dissipating any static charge generated by the conveyed material. Yes, this anti-static property is permanent and does not degrade over the hose's operational lifespan, provided the grounding connection is maintained.

- Q3: What are the typical working and burst pressures for the 30mm ID PU hose?

- A3: For the 30mm ID hose, working pressures vary by thickness. For 0.6mm, it's typically around 1.5-2 bar; for 0.9mm, 2.5-3.5 bar; and for 1.5mm, 4-5 bar. Burst pressures are generally 3 to 4 times the working pressure. Always factor in a safety margin for your specific application.

- Q4: Can this hose be used for conveying liquids or slurries?

- A4: Yes, our polyurethane hose is suitable for conveying various liquids and light slurries, provided the viscosity and chemical compatibility are within PU's resistance limits. The smooth inner bore helps maintain flow. For specific aggressive chemicals or heavy slurries, please consult our technical team.

- Q5: What are the common inspection standards that Kebing hoses adhere to?

- A5: Kebing hoses are manufactured and tested in accordance with international standards such as ISO 9001 (Quality Management), DIN 2605 (for specific hose types), ASTM standards for material properties (e.g., D3389 for abrasion), and relevant ATEX guidelines for anti-static performance (e.g., TRBS 2153, IEC 61340-4-1). We can provide specific test certificates upon request.

- Q6: How does the lifespan of a PU hose compare to PVC or Rubber hoses in abrasive applications?

- A6: In abrasive applications, a high-quality spiral pu hose typically lasts 3-5 times longer than PVC hoses and 2-3 times longer than rubber hoses. This significant difference is due to PU's superior abrasion and tear resistance, leading to lower total cost of ownership over time.

- Q7: What is the typical lead time for custom orders?

- A7: Standard stock items can be dispatched within 3-5 business days. For custom orders, lead times typically range from 2 to 4 weeks, depending on the complexity, volume, and current production schedule. We provide an estimated delivery date upon order confirmation.

Delivery & Quality Assurance:

Kebing understands the critical nature of timely deliveries in industrial operations. We maintain a robust inventory of standard products and leverage efficient logistics partnerships to ensure prompt shipping worldwide. Our production capacity allows us to fulfill large orders while maintaining strict quality controls.

- Certifications: Kebing is an ISO 9001:2015 certified manufacturer, demonstrating our commitment to consistent quality management. Our products comply with various regional and international safety and material standards.

- Traceability: Each batch of polyurethane hose is traceable back to its raw materials and production parameters, ensuring accountability and facilitating rapid problem-solving if any issues arise.

- Packaging: All hoses are securely packaged to prevent damage during transit, whether shipped as coils, on reels, or in customized crates.

Warranty & Customer Support:

We stand by the quality and performance of our products. Kebing offers a standard warranty on all our hoses, covering manufacturing defects and material failures under normal operating conditions. Specific warranty terms will be provided with your quote.

Our commitment to customer satisfaction extends beyond the sale:

- Expert Technical Support: Our team of experienced engineers and product specialists is available to provide pre-sales consultation, assist with hose selection, and offer post-sales technical guidance.

- Responsive Service: We pride ourselves on quick response times for inquiries, quotes, and issue resolution. Our global sales and service network ensures local support where needed.

- Long-Term Partnership: Kebing aims to be a long-term partner for your flexible hosing needs, offering ongoing support, product development, and solutions as your operational requirements evolve.

Further Reading & Industry Insights:

For more in-depth information on industrial hose standards, material science, and safety guidelines, we recommend exploring the following authoritative sources:

- NAHAD - The Association for Hose and Accessories Distribution: Provides valuable resources on hose safety, technical handbooks, and industry best practices. (www.nahad.org)

- ASTM International (American Society for Testing and Materials): Offers numerous standards for testing and specifying materials like polyurethane. (www.astm.org)

- ISO (International Organization for Standardization): Publishes quality management (ISO 9001) and specific product standards relevant to industrial hoses. (www.iso.org)

- Chemical Engineering Journal / Journal of Industrial & Engineering Chemistry: Academic publications often feature research on advanced materials for industrial applications, including polymers and composites used in hoses. (Search via academic databases like ScienceDirect or Google Scholar for recent articles on "polyurethane material science" or "anti-static polymers")

- German Social Accident Insurance (DGUV) – TRBS 2153: Technical rules for operational safety regarding static electricity, highly relevant for anti-static hose applications in ATEX zones. (Information often available on DGUV website or through German industry safety associations, e.g., www.dguv.de/ifa/fachinfos/static-electricity/index.jsp)

-

Strong suction and flexibility: The versatile application of PVC suction hosesNewsAug.05,2025

-

Steel wire reinforcement, tough protection: The road to upgrading the strength of Wire Reinforced PVC HoseNewsAug.05,2025

-

Resilience and Flexibility Coexist: A New Industrial Perspective for Pvc Air HosesNewsAug.05,2025

-

Pulse of Efficient Transmission: The Excellent Performance and Multiple Applications of PU Pneumatic HoseNewsAug.05,2025

-

Enduring Pressure: The Industrial Mission of High Pressure Lay Flat HoseNewsAug.05,2025

-

Durable Water Conveyance: The Practical Value and Technical Charm of PVC WATER HOSESNewsAug.05,2025